Modern Solutions

Concept

It all starts with a challenge: a broken piece, an obsolete component, or a custom feature. Next Gen Designs utilizes years of product development experience to solve unique problems with equally unique solutions.

Design

Advanced Computer-Aided Design (CAD) transforms concepts into fully detailed designs in a virtual environment. Changes can be made rapidly and easily to fully customize a design before any physical material is used.

Production

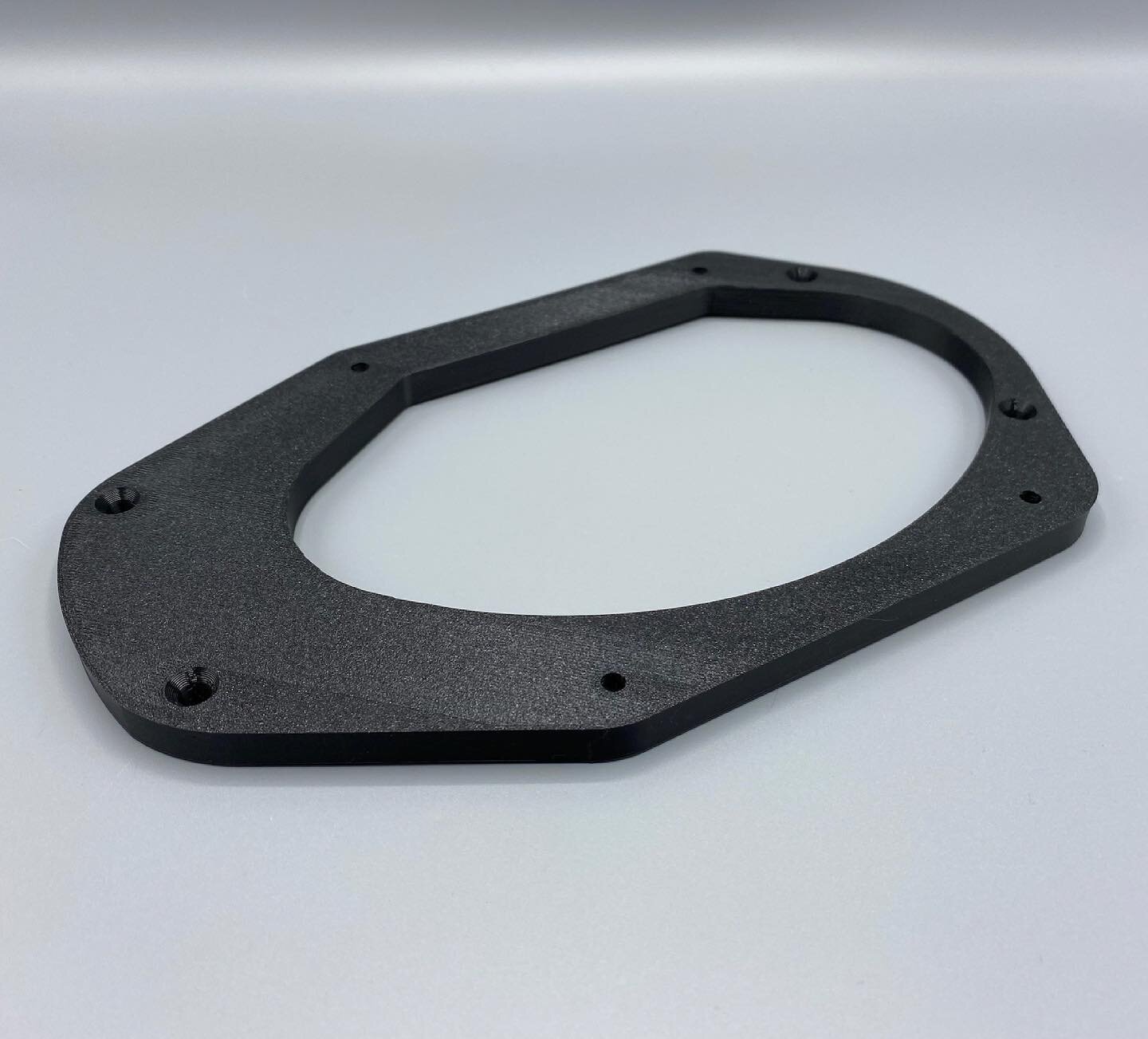

Transforming a design into reality is the final and most exciting step of the process. Next Gen Designs utilizes the latest in 3D Printing and CNC machining technology to rapidly and efficiently bring designs to life.

CAPABILITIES

3d scanning

3D Scanning technology allows complex objects to be converted into a digital file for reverse engineering or duplication. Next Gen Designs is proud to offer scanning services to reproduce damaged or obsolete parts with precision.

cad modeling

Next Gen Designs utilizes advanced Computer Assisted Design (CAD) software to create digital component designs from scratch. CAD designs are developed to fit a customer's unique needs and specifications for their application.

fdm 3d printing

Fused Deposition Method (FDM) 3D printing builds components by depositing plastic filament in fine layers, making this the ideal process for strong and complex parts. A variety of different materials are available with varying properties for maximum customization.

LCD 3D PRINTING

Liquid Crystal Display (LCD) 3D printing utilizes a high resolution LCD display to selectively harden UV-sensitive liquid resin. Because the process utilizes fine light, this process is ideal for high quality cosmetic parts.

CNC MACHINING

CNC machining converts many lines of computer code into precise movement of cutting tools to form complex parts from large blocks of material. With a wide array of cutting tools and programming parameters parts can be made from virtually any material.

WELDING

When multi-component assemblies are required, welding is the key process that brings the parts together. Tungsten Inert Gas (TIG) welding is a precise, controlled welding process which produces high strength and high quality joints.